They are still widely sold because they are cheap and offer a "universal" fix for loose chains.

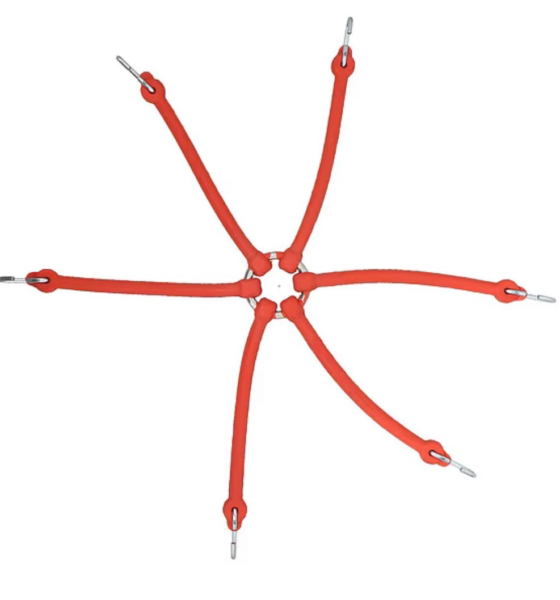

1. Rubber Ring / Donut-Style Tensioners

Main Limitations

- Material fatigue: Rubber hardens, cracks, or loses elasticity over time—especially in freezing temperatures, UV exposure, or contact with salt and road chemicals.

- Uneven tension: Because tension is applied around a single circular band, it doesn’t always pull chains evenly, which can lead to slack in one area and over-tension in another.

- Limited tension strength: For heavier vehicles or deep-snow conditions, they simply can’t generate enough pull to keep chains perfectly centered under load.

- Short lifespan: Often need replacement every season, particularly with frequent use.

- User errors: Many users over-stretch them or install them off-center, leading to early breakage or chain slippage.

Typical Failure Mode

Rubber snaps or slips off a chain lug; chain loosens, starts slapping the wheel well, or rides unevenly on the tire.

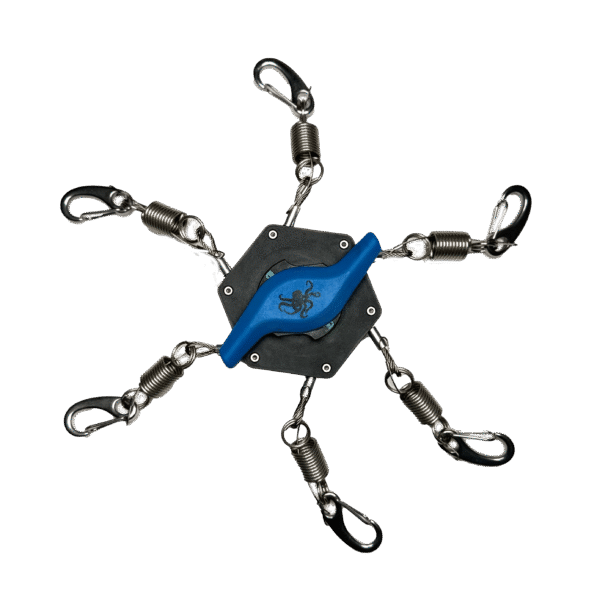

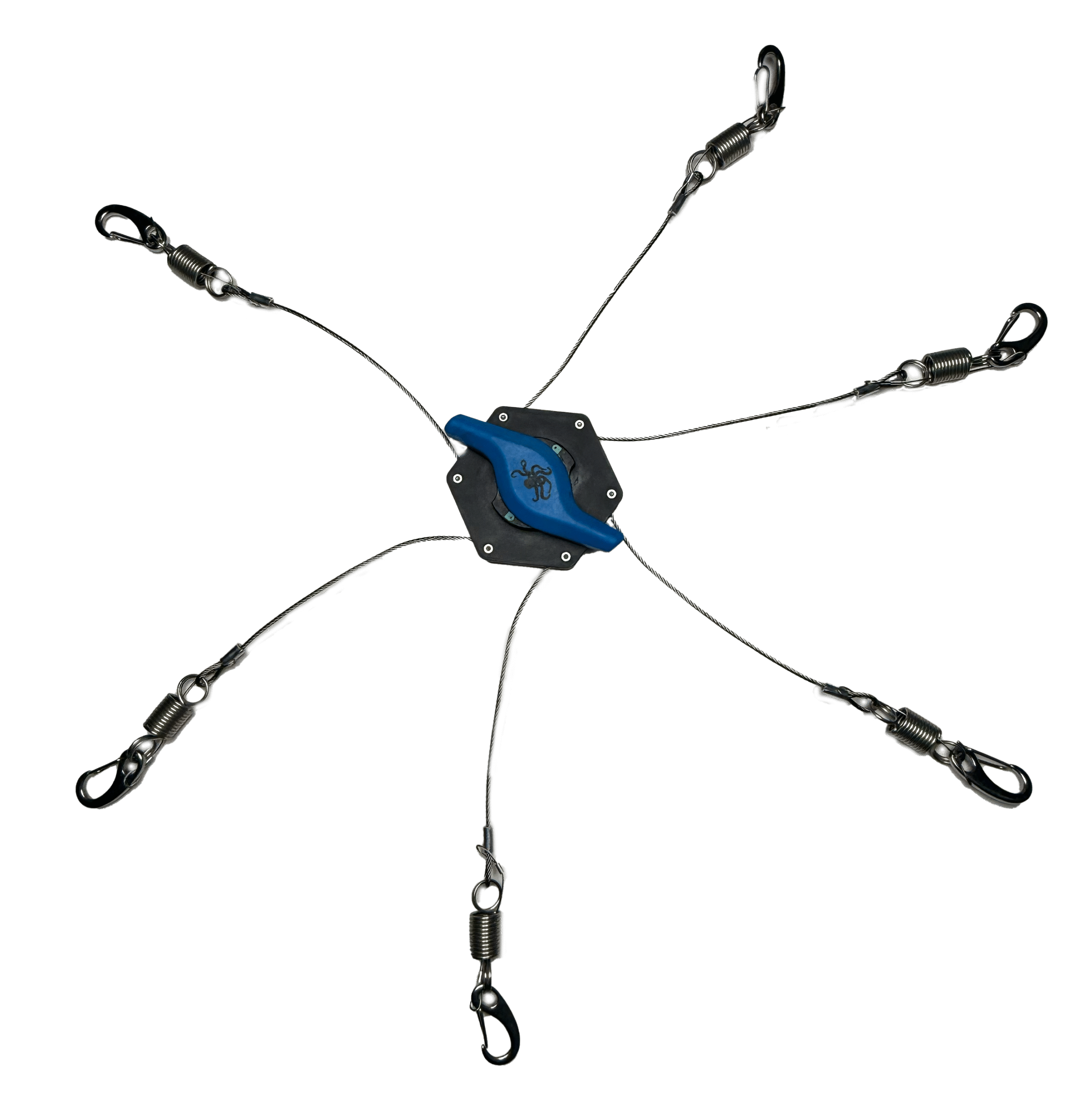

2. Spider / Bungee-Arm Tensioners

Main Limitations

- Complex installation: Requires even placement and correct hook distribution; users often mis-hook one arm, causing imbalance.

- Elastic degradation: Though more robust than single rings, the rubber arms still degrade from UV, ozone, and cold, particularly at the base of each arm where stress concentrates.

- Hook corrosion or failure: Metal hooks (often bare steel) rust and weaken, especially in salted environments.

- Loss of symmetry: If one arm loses tension or breaks, the whole system becomes unbalanced and less effective.

- Bulk and interference: Central hub can occasionally rub against wheel caps or protruding lugs on some tires.

Typical Failure Mode

One or more arms snap under tension; chain starts shifting on one side, forcing driver to stop and readjust.

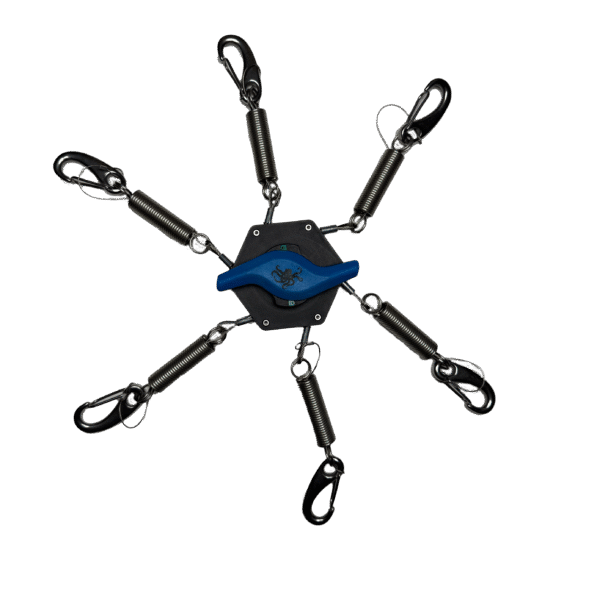

3. Spring / Metal Tensioners

Main Limitations

- Corrosion: Metal springs are prone to rust if not stainless or zinc-coated. Once corroded, tension strength drops and hooks can seize or snap.

- Difficult to install in cold: Stiff springs require force — gloves make it tricky; cold metal can cause hand injuries or fatigue.

- Over-tension risk: Can overtighten and distort chain alignment, leading to premature wear or even broken cross-chains.

- Noise and vibration: Springs can rattle or click during rotation, causing driver concern or mechanical wear.

- Compatibility: Not all spring systems fit all chain geometries or tire sizes; mismatched tensioners can actually cause more harm

Typical Failure Mode

Rust-weakened spring snaps or unhooks, flinging the chain loose; or overtightened chain breaks under torque during acceleration.

Automatic / Self-Tightening System

Main Limitations

- Cost & complexity: Built-in ratchet or cam systems dramatically increase cost and have more moving parts that can jam or freeze.

- Limited repairability: Once the mechanism fails (frozen ratchet, broken strap), the entire system often must be replaced rather than repaired.

- Fit specificity: These are highly vehicle- and tire-specific — users can’t easily transfer them between different tire sizes or chain models.

- Cold-weather jamming: Automatic tensioners can freeze solid in slush or packed snow, preventing proper self-adjustment.

- False sense of security: Some users assume “automatic” means maintenance-free; in reality, they still need inspection and manual tightening after initial use.

Typical Failure Mode

Internal mechanism seizes or fails to re-tension mid-drive; chains slacken and can strike body panels.

OVER 21% OF ALL CAR CRASHES

Over 21% of the nearly 5.9 million car crashes in the U.S. each year are weather-related, with more than half a million caused by snow, sleet, icy, or slushy pavement.

~156,000 CAR ACCIDENTS

Each year, about 156,000 car accidents in the U.S. are due to icy roads.

116,000+ Americans Injured

More than 116,000 Americans are injured annually in winter driving accidents.

1,300 Deaths / Year

Winter driving conditions cause over 1,300 deaths per year in the U.S., with icy roads responsible for about 70% of these fatalities.

12 Billion USD / YEAR

Winter driving accidents cost the U.S. economy over $12 billion every year.

10× Stopping Distance

Driving on snowy roads can increase stopping distance by up to 10 times.

Every winter, millions of drivers across North America face severe risks due to icy and snowy roads.

GET IT TODAY!

ENGINEERED TO WORK, WITH YOUR SAFETY IN MIND

The Kranken

Built for the daily driver; cars, SUVs, and light trucks. The Kranken delivers the same rugged engineering as our larger model in a size made for everyone. Tough enough for the harshest conditions, yet easy enough for daily drives. Keep your chains locked tight so you can travel with confidence.

Kranken XL

Brings unmatched strength and reliability to heavy-duty vehicles with larger tire sizes. Engineered for the most demanding roads, it keeps chains secure through the toughest hauls and harshest storms.